The Graphene Revolution May Be Around The Corner

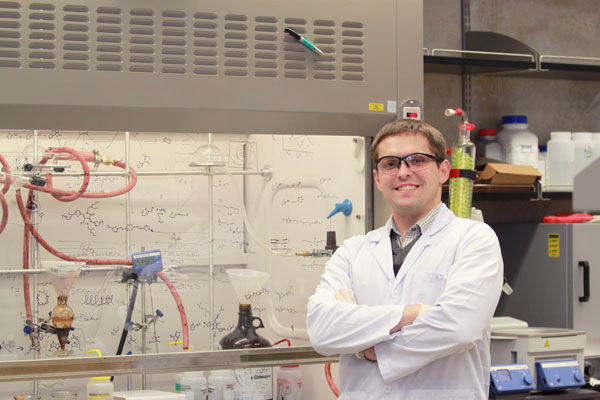

This is exactly the problem that Alex Zaretski, a UC San Diego doctoral candidate, is trying to solve. In 2013, Zaretski founded GrollTex, a company that is in the process of patenting a method for mass-producing graphene sheets of various sizes. If GrollTex is successful, it could be poised to supply a fundamental component to companies across many different industries.

“There are more than 8,000 possible graphene applications that have been already patented, and all those applications are sitting on their virtual shelves,” he says. Everything from graphene helmets to solar cells, even the use of graphene to treat epilepsy can be found with a quick search of the patent office. But without a source of inexpensive graphene to implement, these patents are useless.

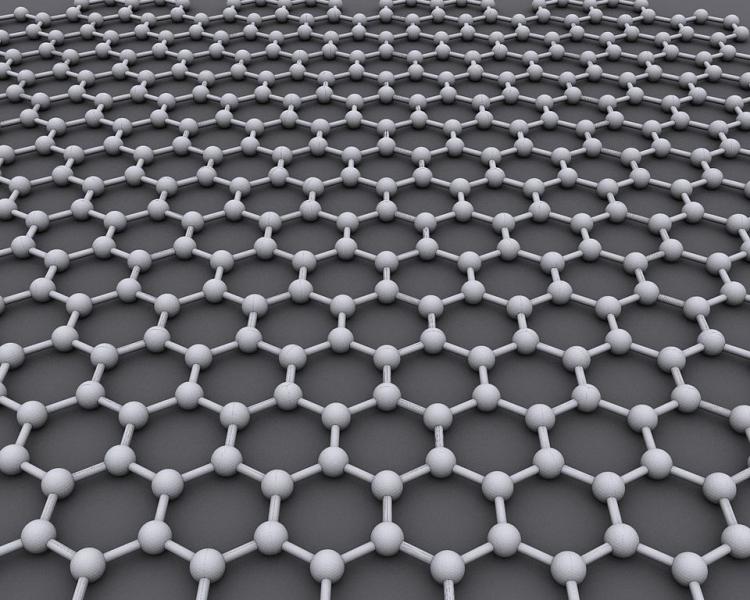

Graphene is basically a sheet of carbon atoms arranged in a honeycomb pattern. These sheets are so thin, only one atom thick, that they are said to be the closest possible material to being truly two-dimensional. The material is also super strong, flexible, transparent, lightweight, and conductive to electrical currents.

This combination of properties makes graphene a valuable resource in a wide range of industries, from solar panels and lithium battery production to electronic displays and aerospace engineering. Investors have poured money into researching graphene, but so far the money has stayed in research and development, with few products making it to the mass market.

The first graphene sheet was created by University of Manchester scientist Dr. Andre Geim and his pupil, Konstantin Novoselov, who shaved a graphite crystal (the same material used in pencils) down to its most basic layer. The discovery prompted Geim to remark, “You polished a mountain to get a grain of sand?” The scientific community gradually realized graphene’s importance, and awarded the Nobel Prize to the two discoverers in 2010.

Since then, several more graphene innovations have come about. GrollTex is only one of many companies and labs producing graphene. Big players like Samsung Electronics Co., for one, is a leader in the corporate sphere, but research labs worldwide are producing graphene using different methods.

GrollTex’s process does not produce as high-quality graphene as some other methods, according to Swedish researcher Mikael Syväjärvi of Linköping University, but it has an advantage in that it can be transferred to flexible electronics.

GrollTex Chief Executive Jeff Draa saw the potential in Zaretski’s idea while judging UCSD’s Entrepreneur Challenge. The two formed a partnership after Zaretski won the competition. He sees GrollTex’s most immediate area for growth in screens for electronic devices. “The display market is ripe for a disruption like this,” he says. “Graphene, via our method, would enable flexible displays, so that’s a real game changer for the display industry.”

Flexible, in this case, doesn’t mean the screen will just give a bit. A graphene phone could potentially touch its top to its bottom, or even wrap around an arm like a watch. “It’s the strength of diamond,” Zaretski says, “but it is one atom thick so it’s extremely flexible.” Who wouldn’t want an unbreakable screen for their smartphone? Samsung has already experimented with flexible screens, and has even developed some flexible smartphone prototypes.

Samsung has led the world’s research into graphene so far, but by all accounts is still limited by the same production obstacles that are keeping the industry from taking off. Graphene sheets, as they are produced today, are grown on foil, like aluminum kitchen foil, but instead made out of copper. This process is not conducive to producing large-area graphene for several reasons. To separate the graphene from the copper once it is grown, the copper must first be dissolved, a time-consuming process that creates a toxic byproduct. Once dissolved, of course, the copper cannot be reused, making the process extremely expensive.

The “secret sauce,” as Zaretski puts it, of GrollTex’s production method is that they no longer have to dissolve the copper foil. In fact, they are able to reuse it, reducing waste and saving on costs – savings they plan to pass on to customers. “So basically, in three words, we use metal as glue to rip graphene off of copper.” Of course, if it were that simple, everyone would be doing it. Zaretski’s discovery came after years of painstaking research at UCSD and Cornell.

“It was a sweet eureka moment, really, when I found this – that it worked,” says Zaretski. “Being a grad student stuck in a lab with a project not working out for a year isn’t the sweetest of sensations.” Zaretski says GrollTex plans to be operational by June of 2016, and producing large-area graphene shortly thereafter.

A recent report predicts the global graphene market to be valued at $278.47 million by 2020, rising by 42.8% over the next five years, according to Indian research firm Markets And Markets.

GrollTex’s team is also looking beyond simply producing graphene to developing applications of its own. They plan on implementing microscopic graphene sensors that could detect minute changes in heartbeats and other body processes. Since graphene sheets are so thin and transparent, it may be that the true graphene revolution will be invisible to the naked eye.

Because of graphene’s microscopic nature, extensive research is required to guarantee its safe application in these fields. Since graphene has only been discovered so recently, little is known on the effects of inhaling small particles of the material into the lungs, or otherwise absorbing graphene into body tissue.

A team of researchers at Brown University published findings in 2013 asserting that sharp edges of graphene sheets can easily pierce cell membranes, possibly disrupting normal cell function. Since then, safety guidelines have been suggested for the study and development of graphene, which if adopted, “could reduce the overall health risk to a minimum for workers developing graphene,” according to the European Commission.

Inhalation of graphene particles is only a risk to those creating “micro-exfoliated graphene,” according to Zaretski. This is made by blending graphite with a certain solution, which is then sprayed onto materials like glass to give them conductive properties.

In order to be certain graphene is the miracle material many hope it to be, extensive research is necessary. While it may be painful to sit and wait for the future to arrive, in the case of chemical science, patience is a virtue – and can possibly prevent disaster.

Reach Contributor David Merrell here. Follow him on Twitter here.